There are several different types of central heating boiler available to householders in the UK but deciding which one to install is affected by several factors:

• Type of Fuel – This will obviously depend on which types of fuel are available in the area and although the vast majority of UK homes have a gas supply, those in remote areas may have to rely on oil, LPG, Solid Fuel or renewable energy such as solar.

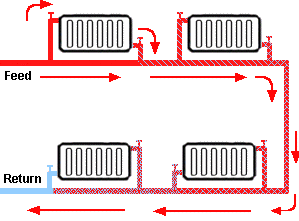

• Boiler Size – It may seem obvious that the size of the central heating boiler (in terms of its output) will need to reflect the needs of the household in respect of how many radiators it has to warm and the demand for hot water, but the space available will also dictate the physical size of the boiler which can be installed.

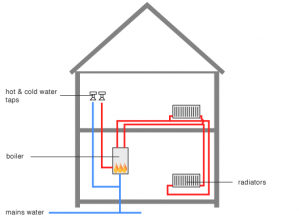

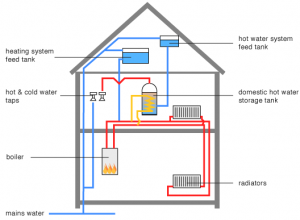

• Household Requirements – A combi boiler which heats water as it is required may be acceptable in a small house or flat where the demand for hot water is relatively low but it would be unsatisfactory in a large household where several occupants may wish to use hot water at the same time.

• Renewables – The inclusion of renewable sources of heat energy in a domestic central heating system can affect the type and size of boiler to be installed as there would be normally more than one type of energy used.